AcamMill9 Module

CNC Milling with a different

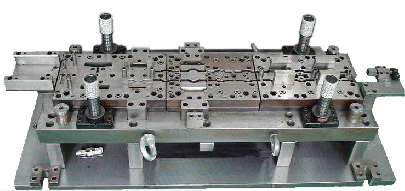

AcamMill9 is a fast & simple, factory certified CAM system with Process Oriented Programming method for milling. The software provides a powerful practical knowledge-based machining technology that requires little skills yet allows the optimization of productivity of the CNC machining centre. AcamMill9 is created for production milling as well as holes processing where the engineer can totally control the cutting processes such as directing the cutter to plunge in or leave the workpiece, as well as powerful machining strategies like parallel roughing and undercutting. All holes processing strategies can be stored for future use as there is no need to redefine the process again. With high-efficiency humanize hole processing. spiral down machining for profiling and other unique features that help to increase the productivity of the CNC milling.

AcamMill9 Features

AcamMill9 Advantages

Users definable cutting processes.

Auto tool selection with tool library.

Colors visual for easy selection and viewing.

Datum and depth can be picked directly from the side view of the drawing.

Same job in multi views programming.

Auto feed rate reduction at internal ARC.

Auto RPM & feed rate adjustment accordingly to cutter length projection.

Smart Features

Using colors for easy selection and viewing.

Fully customizable Post, Rpm and Feedrate data.

What you see is what you get – Same cutter path is display.

Working directly inside Acad or eCad, no addition command to learn.

Profile – Separate 3D step for taper and radii.

Profile – Text engraving in straight line or arc.

Profile – Plunge cut machining with/without taper.

Profile – Manual cutter path modification is possible.

Profile – Cutter path simulation for profile and cycle.

Profile – Cutter path verification for small corner radius.

Profile – 2.5D profiling with different top and bottom radii.

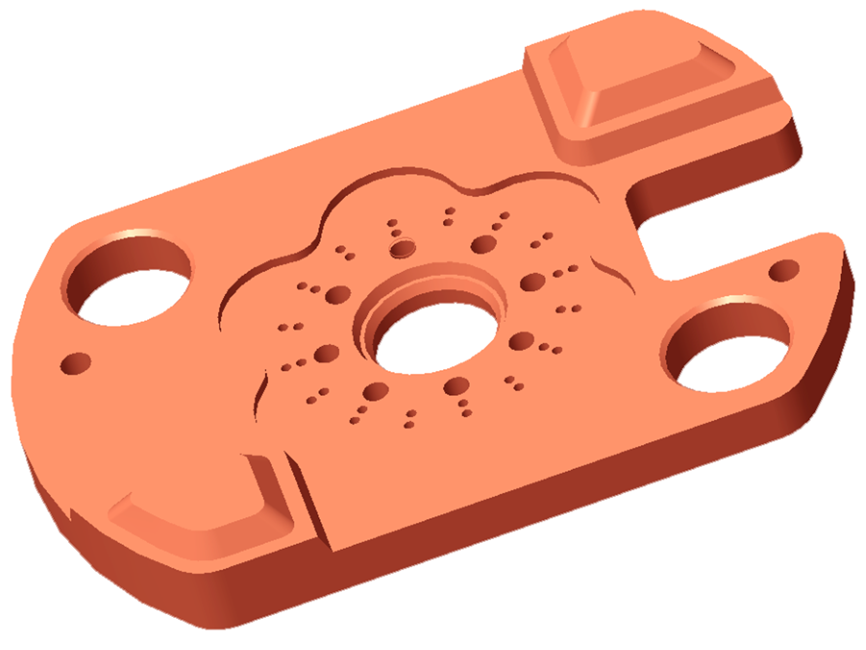

Profile – Regular pocket with different taper angles for roughing & finishing.

Cycle – Automatic recognition of tap hole.

Cycle – Automatic depth calculation for plate drilling

Cycle – Automatic mirror file for holes with hidden line.

Cycle – Automatic generation of pre-ream and tap drill hole.

Cycle – Automatic depth for center drill of different diameters.

Cycle – Automatic generation of step drill for large diameter hole.

Etc.

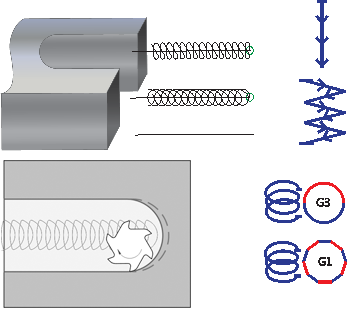

Holes Processing

All holes processing strategies can be stored for future use as there is no need to redefine the process again. With high-efficiency humanize hole processing. spiral down machining for profiling and other unique features that help to increase the productivity of the CNC milling.

Regular profiles

2.9D function for regular 3D profiles.

Separate 3D step for taper and radii.

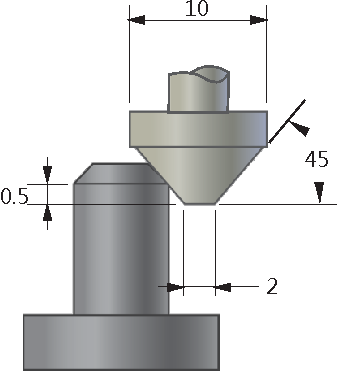

Chamfering

The chamfering auto-calculate

depth and offset.

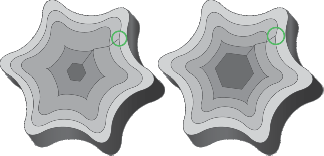

Intelligent Variable Offset

It can reduce up to 30% of machining time.

Auto RPM & feed rate reduction

according to a total depth of cut.

Text Engraving

Text engraving on curve

or slant surfaces.

Text can be projected and

engrave it out.

Corners Milling

Unique function for corners.

Auto generation of cutter path for

corner re-machining.

Auto feed rate reduction or increase

at corners.

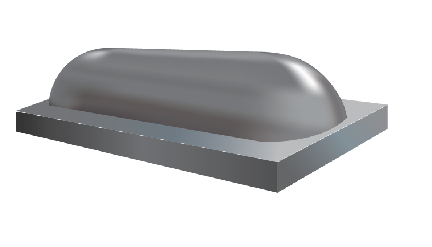

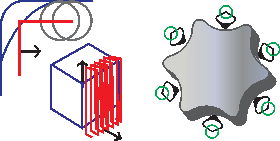

Trochoidal Milling

Trochoidal Milling allows high metal

removal rate for roughing.

Selectable cutter approach and

departure patte