AcamWire9 Module

ACAM wirecut with a different

AcamWire is a highly competent CAM software that reconmended by wirecut EDM manufacturers like Sodick , Mitsubishi, Makino, Charmilles, Exceteck etc . You can regenerate the NC for any wirecut EDM without reprepare the complicated profile once switch over seamlessly amangst different wirecut EDM in your production line.

Acam has more than 20 years application experience in supporting precision engineering industry in Singapore, Malaysia and Indonesia. There are more than 70% regional precision engineering companies are using AcamWire.

Auto Check Internal Corner

Rough & Finishing Cutting

AcamWire9 Features

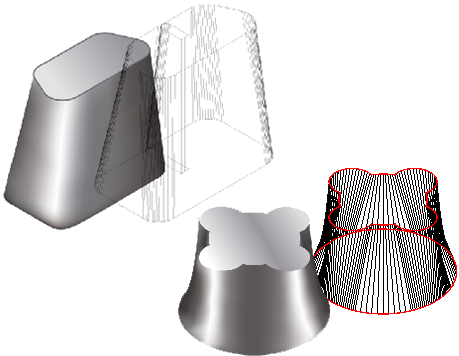

4 Axis Wire EDM tecnology +B Axis

The AcamWire9 support 2 & 4-Axis wire EDM machine plus B Axis.

It provides an extensive knowledge-based machining technology with stored information likes wire diameter, material, cutting conditions and offset to generate highly efficient machining codes.

Loaded with exclusive high precision and productivity cutting strategies for you to choose.

The AcamWire9.8 is straight forward and quick to learn yet powerful software for Wirecut machining with many key features.

Die Profile Unique Cutting Features

Able to do forward and reverse cut.

Coreless type cutting for small holes.

Possible with auto hold and overcut.

Start hole can be outside profile.

Hole with different approach directions.

Auto oil-hole approach undercut.

More than ten types of corner undercut.

Auto rotate approach direction for the hole.

Four types of approach pattern to select.

Overcut is possible to have negative value

More…

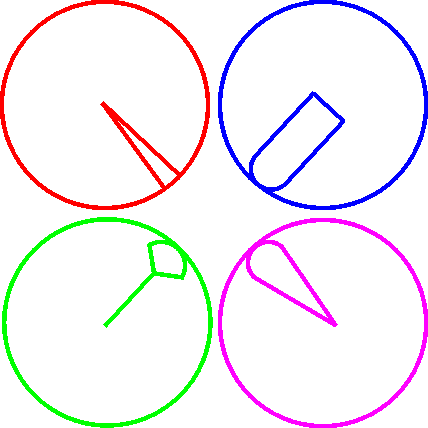

Approach Pattern

One linear mode &

3 circular mode

Type1 Type2

Type4 Type3

Coreless Cutting

Die profile with no slug after machining

to prevent wire break

Punch Profile Cutting Features

Auto single or multi holds

Auto part off with 2nd stop

Able to define sharp corner cutting

Auto part off with recess as no grinding required

Auto part off with material left for grinding

Three types of sharp corner machining methods

Display of maximum holding length available

Auto single or multi-hold for part-off.

Possible to have circular approach & departure

Auto part off with recess as no grinding is required

Auto part off with the same number of cut as punch

More…

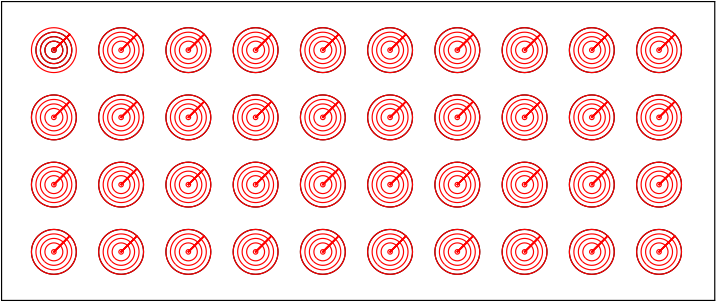

forward reverse

Forward & reverse direction cutting to achieve the better roundness or squareness

1st_cut 2nd_cut 3rd_cut 4th_cut

Forward & reverse direction cutting to achieve the better roundness or squareness

Machining Fault Checking & Reducing Features

Auto wire offset direction, G41 & G42 selection

Flexible zero (datum) point

WYSIWYG, wire path is the actual NC path

Usually, generated NC file do not require editing

Auto check for short line & small arc with direct modification

Able to input clearance for each profile

Able to graphic check a manually edited NC file

More…

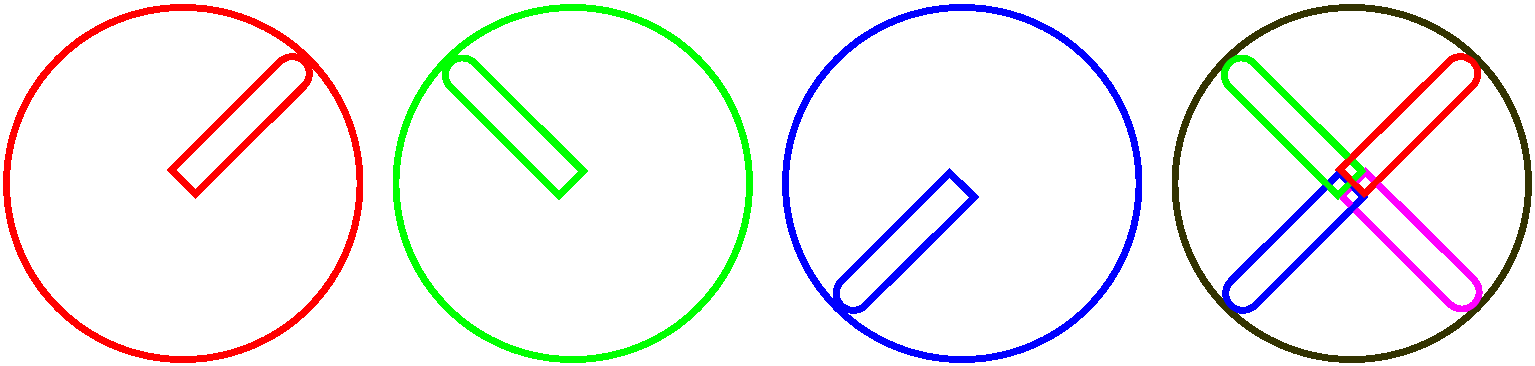

Dummy Point

Clamp

Dummy or Transition Point

The machine travel to the transition point before go to next profile start point. It’s used to avoid the clamps

Generating NC using Machining Strategies

AcamWire9.8 provide the following cutting strategies to resolve the critical cutting requirement.

Normal- Punch/Dies

Finish all Cuts (123) in 1st profile

then go to next profile

Precision- Punch/Die

1) Cut all 1st cut (111)

2) Follow by trim cut 1-by-1 (23,23,23)

High Precision- Punch/Dies

1) Cut all 1st cut (111)

2) Cut all 2nd cut (222)

3) Cut all 3rd cut (333)…

Auto Arrey- Punch only

S1) Punch + Dies cutting Strategy 1

1) Punch 1st cut

2) Dies all cuts

3) Dies trims cut

4) Last, Punch trim & part of

S2) Punch + Dies cutting Strategy 2

1) Punch 1st cut

2) Dies all cuts

3) Dies trims cut

4) Last, Punch trim & part off

S2) Punch + Dies cutting Strategy 2

1) Punch 1st cut

2) Dies all cuts

3) Dies trims cut

4) Last, Punch trim & part off

S3) Punch + Dies cutting Strategy 3

1) Punch all cut

2) Dies 1st cuts

3) Dies trims cut

4) Last, Punch trim & part off

S4) Punch + Dies cutting Strategy 4

1) Punch all cut

2) Dies all cuts

3) Last, Punch part off

S5) Punch + Dies cutting Strategy 5

1) Punch 1st cut

2) Dies all cuts

3) Last, Punch trim & part off

S6) Punch + Dies cutting Strategy 6

1) Dies 1st cuts

2) Dies trims cut

3) Last, Punch all cut & part off

Productivity Enhancement Features

Flexible datum point definition

Able to do full or partial taper in any cut

User definable cutting condition data bases

Prepared path can be edited with new settings

Prepared path is able to copy, rotate and array

Able to display cutting perimeter, time and cost

Just change the prepared wire path color

will alter the number of cut in 1 second.

Special function for unman overnight cutting

Prepared wire path can be edited, pulled,

stretched, copied, rotated or arrayed.

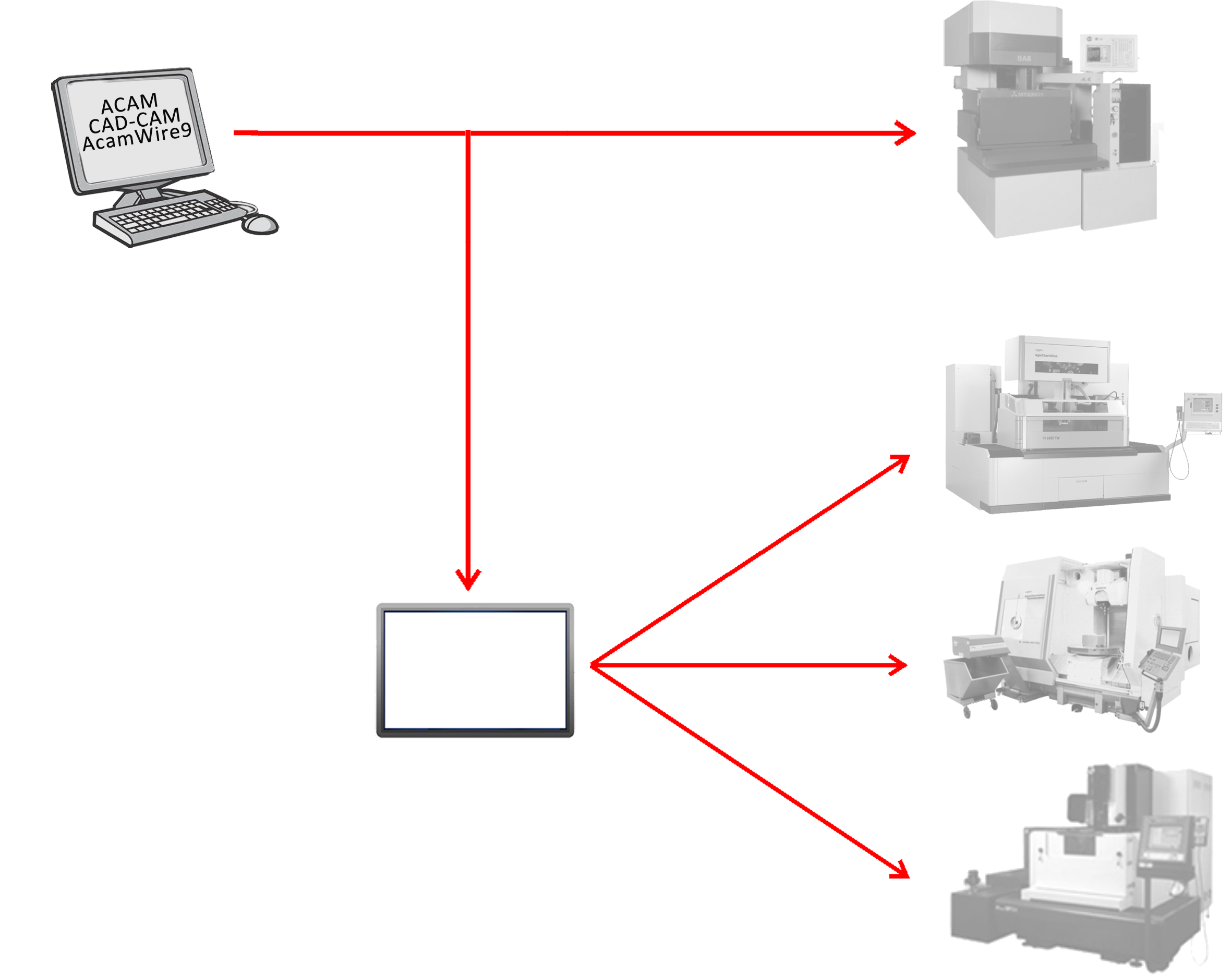

Prepared wire path can be posted to different machine

formats without reprepare in 5 seconds

More…

change

NC of Wirecut-1

to

Wirecut-2 /3 /4

When your current working machine down, just apply the Convert Function to change all local condition same for the standby machine, then output the NC again.